| SDC Forum #108664

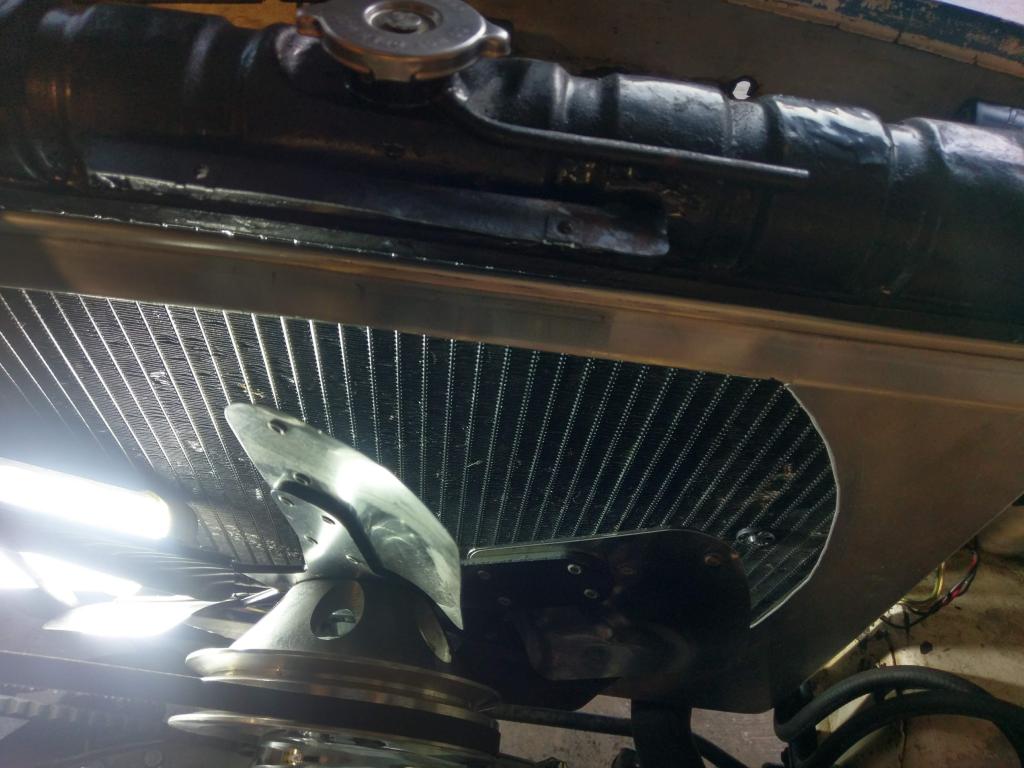

Im sure I’ll get some -ahem- HEAT for this as its not stock, but here we go: I used an aluminum cooking pan, some aluminum angle metal, some galvanized roofing material and a lot of rivets. I probably measured and re-measured about 50 times, improvised along the way, and pulled the radiator out 10 times to make sure it all fit. One challenge I ran into was the bolts that hold the radiator to the radiator mount: they were a bit stripped so I needed to tap the threads in the mount. It was a bit of a detour, but necessary. Note that if you do this, there is a metal rod inside the rolled pan edge. I wasnt expecting that to be there. The pan was just about the correct width: I had to cut some notches for the bolts that hold the radiator in place. The angle metal that was used to bolt the shroud to the radiator mount needed to be opened up to get the angle right. I it with a hammer to open that 90degree angle up to the necessary angle so it sat flat when bolted to the support. Note that this Fan Shroud was attempted after cleaning out the water jackets, replacing the water pump, and re-rodding the radiator- which made no difference in the temperature. So this was the next logical step in the attempt to get the temperature down. Its not the prettiest shroud, but it made a HUGE difference in the temperature. Check out the photos, and let me know if there are any questions. Im sure some of you will have some suggestions as well…

|

|

|