| Author |

Topic Topic  |

|

|

PlainBrownR2

Commander Member

USA

1901 Posts |

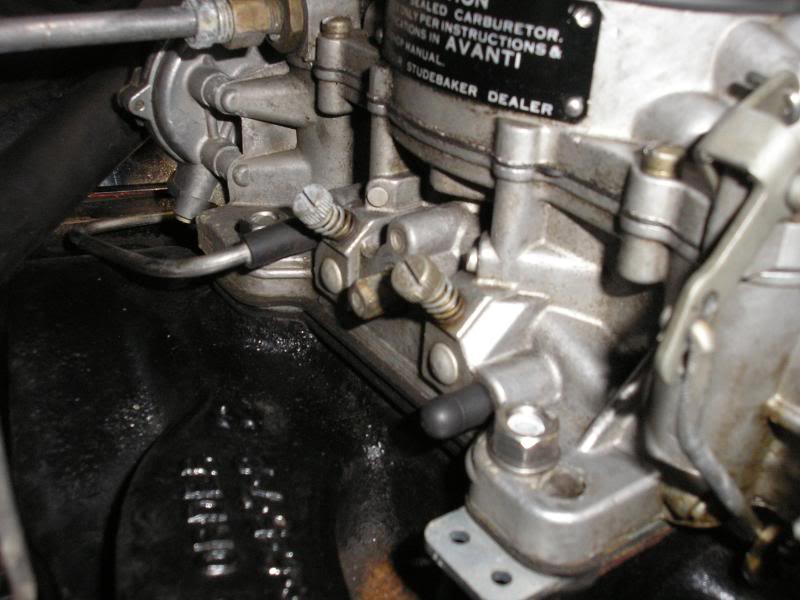

Posted - 03/02/2010 : 8:19:06 PM Posted - 03/02/2010 : 8:19:06 PM

|

Hello,

Since the Racing forum is currently indisposed at the moment, I need a little age and wisdom on this subject   .

On the Lark, I have an R2 carburetor, that while replacing some intake

manifold gaskets to resolve an idling problem, that I discovered that

one of the carburetor's mounting tangs is cracked. Turning up another

carburetor for parts has yielded little results, therefore I was

wondering: .

On the Lark, I have an R2 carburetor, that while replacing some intake

manifold gaskets to resolve an idling problem, that I discovered that

one of the carburetor's mounting tangs is cracked. Turning up another

carburetor for parts has yielded little results, therefore I was

wondering:

Can the R2 carburetor be converted to use an

Edelbrock base with a Carter top? If not, that nulls out the subsequent

set of questions  . .

What model of Edelbrock can be used for the conversion (1403, 1404, 1406, etc)?

What jets, rods and springs need to be used for the conversion?

Are there any vent holes to seal and redrill in the base?

Any other modifications that need to be done to use the Edelbrock base?

Is

there anything different about the Edelbrock base that will not allow

this to work? We picked up some regular R1 carbs, but when we flipped

them over we found the warming passages were completely different.

|

|

|

IMJ

Champion Member

USA

21 Posts |

Posted - 03/02/2010 : 8:55:19 PM Posted - 03/02/2010 : 8:55:19 PM

|

Hello,

I

certainly don't have the wisdom but I do know that a friend of mine has

an Edelbrock with a Carter AFB top on it. I do not know what model he

has. Sorry I can't be more help, I just replied so you know it is

possible. He also bought a new reproduction sealed AFB that I think

Dave Thibeault assembled that looks almost identical to an original.

regards,

Jay |

|

|

|

PlainBrownR2

Commander Member

USA

1901 Posts |

Posted - 03/02/2010 : 9:04:27 PM Posted - 03/02/2010 : 9:04:27 PM

|

One of the things that people have to keep in mind is the R2 carbs are

sealed, meaning there's no vent holes like that on an ordinary

carburetor. I know this can be done with the regular 259/289

carburetors as they vent normally, but I'm wondering if anybody has

done these with the R2 carburetors. These carbs vent internally because

the blower pressure will spray fuel out of the vent holes on a normal

carb. That's not good, particularly on a driver  . .

Yeah, if necessary I'll get ahold of Thibeault as he does the conversions as well.

|

|

|

|

IMJ

Champion Member

USA

21 Posts |

Posted - 03/02/2010 : 9:41:54 PM Posted - 03/02/2010 : 9:41:54 PM

|

The Edelbrock with the Carter AFB top is being used on an R2 my friend

has in his Cruiser. The only problem he had was with the seal at the

accelerator pump stem. He replaced it twice and the third time he got a

kit for a marine application. The later seal kit also came with a new

accelerator pump. The pump stem is plastic but so far seems to be

working.

regards,

Jay |

|

|

|

Laemmle

Golden Hawk Member

USA

907 Posts |

Posted - 03/02/2010 : 9:57:09 PM Posted - 03/02/2010 : 9:57:09 PM

|

Nick Berger in Westminster Ca runs his R2 with a 500cfm Edelbrock!

quote:

Originally posted by PlainBrownR2

Hello,

Since the Racing forum is currently indisposed at the moment, I need a little age and wisdom on this subject   .

On the Lark, I have an R2 carburetor, that while replacing some intake

manifold gaskets to resolve an idling problem, that I discovered that

one of the carburetor's mounting tangs is cracked. Turning up another

carburetor for parts has yielded little results, therefore I was

wondering: .

On the Lark, I have an R2 carburetor, that while replacing some intake

manifold gaskets to resolve an idling problem, that I discovered that

one of the carburetor's mounting tangs is cracked. Turning up another

carburetor for parts has yielded little results, therefore I was

wondering:

Can the R2 carburetor be converted to use an

Edelbrock base with a Carter top? If not, that nulls out the subsequent

set of questions  . .

What model of Edelbrock can be used for the conversion (1403, 1404, 1406, etc)?

What jets, rods and springs need to be used for the conversion?

Are there any vent holes to seal and redrill in the base?

Any other modifications that need to be done to use the Edelbrock base?

Is

there anything different about the Edelbrock base that will not allow

this to work? We picked up some regular R1 carbs, but when we flipped

them over we found the warming passages were completely different.

|

|

|

|

silverhawk

Commander Member

USA

1751 Posts |

Posted - 03/02/2010 : 10:08:39 PM Posted - 03/02/2010 : 10:08:39 PM

|

Could you possibly fix the crack? I've heard of JB weld doing amazing things, maybe it would work to seal a crack.

Dylan Wills

'61 lark deluxe 4 door wagon |

|

|

|

PlainBrownR2

Commander Member

USA

1901 Posts |

Posted - 03/02/2010 : 10:22:40 PM Posted - 03/02/2010 : 10:22:40 PM

|

It was considered, well by me anyway. But, for something like this, in

particular if the epoxy doesn't hold, the crack spreads, and suddenly I

have a very lean condition, I'd really rather permanently fix, by

replacing the broken part, than try to patch something like this. Plus,

the crack occurred where the base meets the ear of the mounting tang on

the base of the carburetor. It runs around from the bottom of the carb,

up the tang, and over to the thermostatic choke housing where it

stopped. At this point I'm basically running around with 3 1/4 solid

mounting points on the carburetor, so the JB weld would be more like a

cosmetic fix than a permanent one.

For me, this really is one of those situations where the adage "Fix it right or fix it twice" very strongly applies.

|

|

|

|

Milaca

Commander Member

USA

2099 Posts |

Posted - 03/02/2010 : 11:00:53 PM Posted - 03/02/2010 : 11:00:53 PM

|

This won't help you, but your dilemma brings to mind something that

recently happened to me. I have a 1965 International pickup with a snow

plow and it would only run with the choke halfway closed, so I took the

Holley 2-barrel apart and put a new repair kit in it. All was going

well until I was torqueing the four mount bolts to the intake manifold

when I heard a 'SNAP'. Yep, I broke a mounting ear off of the

carburetor base.  This made me very upset and frustrated. But, I decided to try it out

anyway and good news! It runs great! This vehicle wont see many hours

of use, so proper repair isnt too critical.

This made me very upset and frustrated. But, I decided to try it out

anyway and good news! It runs great! This vehicle wont see many hours

of use, so proper repair isnt too critical.

As far as using JB Weld

or other Epoxy, I have found is a waste of time in such an application.

I had a damaged snowmobile carburetor with a broken off mount ear and

tried JB Weld to adhere it back together, but it simply broke apart. JB

Weld may work fine for patching holes, but I dont think it works well

for glueing pieces back together that are subjected to fastening torque.

Autumn at Lake Barget

In the middle of Minnestudea |

|

|

|

Turbopackman

Champion Member

USA

48 Posts |

Posted - 03/03/2010 : 01:30:58 AM Posted - 03/03/2010 : 01:30:58 AM

|

FWIW, I used an Edelbrock, un-modified, on my supercharged '56 Packard

Patrician with ZERO issues. According to vs57.com, an Edelbrock carb is

safe to use up to 8 psi before you have any problems. You can also use

a marine accelerator pump, which is sealed, if you're concerned about

fuel leaks. I never had any problems, and will use an Edelbrock on my

next forced-induction v8....

Eric Boyle

Packard Engineering, LTD.

Wichita, Ks.

<---Posts may contain anywhere from 30-100% sarcasm---> |

Edited by - Turbopackman on 03/03/2010 01:32:09 AM |

|

|

|

jallen

Cruiser Member

USA

160 Posts |

Posted - 03/03/2010 : 02:26:52 AM Posted - 03/03/2010 : 02:26:52 AM

|

Talk to ErnieR, forum name Bige. I know he has experience with

that combination, I think on his R2 Avanti. And he might have

a thread on the process. |

|

|

|

okc63avanti

Golden Hawk Member

USA

577 Posts |

Posted - 03/03/2010 : 06:17:39 AM Posted - 03/03/2010 : 06:17:39 AM

|

Check out Bob Johnstone's web page on carbs. I believe the correct

edelbrock for an R series engine is the 1406. For a supercharger the

carb fuel pump needs to be sealed. Not sure of exact procedure but a

decent carb shop should know how to do this. If you are not picky about

carb finish and you are willing to pay a little more you can order a

marine 1406 edelbrock carb as it is already sealed.

https://www.studebaker-info.org/

John

63R-2386 under restoration & modification

|

|

|

|

bige

Commander Member

USA

1262 Posts |

Posted - 03/03/2010 : 08:14:26 AM Posted - 03/03/2010 : 08:14:26 AM

|

Good Morning...

Adapting

the Edelbrock using AFB pieces is fairly easy. I've had mine on my car

7 years or so and it's been completely trouble free, gives great

throttle response and full throttle performance.

Things

you MUST do...use the primary venturi clusters from the AFB. The air

vent nozzles on the E Carb are shorter and will be exposed to the air

stream. The car will run but wll run very poorly. I also used the

secondary venturis from the AFB though I'm not sure if it was

necessary. There are subtle differences between the E Carb and AFB

secondary clusters and since it's so easy to change them I just did it.

You

must seal the center screw hole in the back of the AFB top. There isn't

a corresponding threaded hole in the E. I just cut a carb screw down,

filed a nut to fit in the opening and used a small 'o' ring as a seal.

Looks original, doeasn't leak.

I used a accel pump seal from a

carb kit that's a big washer with an 'o' ring. This is where my memory

is a little fuzzy because I believe there was some mixing and matching

of pumps to get a good seal in the bore, a good seal in the top but

also allowing for free movement. If it was real difficult to accomplish

I would have a better memeory of the process.

Options...

I

wanted the carb to look as original as possible so that only the keen

Studebaker eye would notice the change so I removed the large vacuum

port in the from of the E carb, tapped it and plugged with a 1/8" pipe

plug. The threaded hole in the rear works fine for the PCV valve and

contrary to some claims that plugs will foul with the PCV valve back

there I haven't experienced anything like that. In fact It's been 3

years since I changed spark plugs. I also bead blastd the E carb to

match the natural finish of an AFB.

Another

option is to do some grinding on the secondary air valve so that it

lays flat like the AFB. I noticed some surging on full throttle high

rpm runs and felt that the shape and position of the E carb's valve

might cause it to stay closed rather than open at full throttle. If you

look at the pictures you can see that the E carb's valve is not fully

closed and I thought boosted air might get under the valve through that

opening and keep the valve from opening all the way or cause it to

flutter.

Another

option but one I highly recommend is tack welding the linkage in the

spot at the screwdriver tip. The secondaries on both the AFB and the E

carb are activated by a spring. The linkage is there to keep them

closed until you floor it and do give a positive mechanical return

function so your car doesn't take off like a Camry. It has been

suggested that even on the AFB boost may actually over power the spring

and keep the secondaries from opening or cause a fluttering. Since the

E carb was not designed for blown engines I questioned whether the

spring tension was different between the AFB and Edelbrock. I can say

that this mod made a BIG difference. I noticed on the first test drive

that I could feel the secondaries kicking in, not a bog just an extra

pull that was never there before.

As

far as jetting goes you can use your original jets and rods they will

interchange right over to the E carb or experiment. The 1406 that I use

ran very well with the installe 98 Primary and 95 Secondary jets. I've

sinced changed the combo a little but every engine is different so what

works for me may not be best for you.

Some tidbits...I run

without a choke. There have been comments that under boost the choke

can be forced closed but also that the choke has a positive effect on

the air flow straightening the stream under boost. You can adapt the

electric choke to the AFB top with linkage mix and match. I've found

that my car runs and starts fine without it so I just plugged the holes

where the shaft was with some small well nuts and screws.

Mounting

an Edelbrock on a Stude manifold does present two clearance issues. The

choke heat tubes are in the way, they just pull out and you don't need

to do anything with the remaining holes. And the main linkage will hit

the manifold. If you have a stick or never plan to install a GM O/D

trans then just cut the offending extension off. If you have hood

clearance then a spacer would work without altering the carb and help

keep the carb cooler if you use a wooden or phenolic style,

Speaking

of accel linkage, use the big hole. I stuck an appropriate size grommet

in there sandwiched between two thin stainless washers. Acually I

modified that set up a little to give a straighter pull.

Lastly,

until I think of something else, the original AFB had a modified base

to keep fuel from leaking past the shaft bushings under boost. I know

one member who had the done to his Edelbrock. I'm not that skilled but

I've never really had an issue with leakage there or at the accel pump.

I also noticed that for the first few miles there would be a little

bubbling around the pump seal but that went away. I guess things needed

to seat.

Email me at r2r5388@yahoo.com if you have any questions.

BTW,

I wouldn't use a marine carb without checking with Edelbrock first.

Something tells me there is a reason they are different other than

sealing.

ErnieR

1988 "Beater" Avanti---R5388 @ Macungie 2006 |

Edited by - bige on 03/03/2010 08:25:33 AM |

|

|

|

jlmccuan

Golden Hawk Member

USA

852 Posts |

Posted - 03/03/2010 : 1:36:48 PM Posted - 03/03/2010 : 1:36:48 PM

|

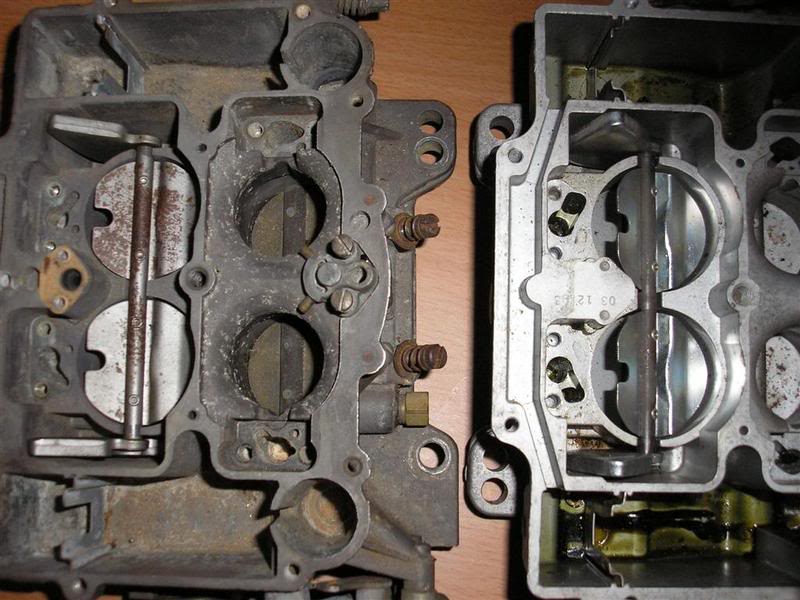

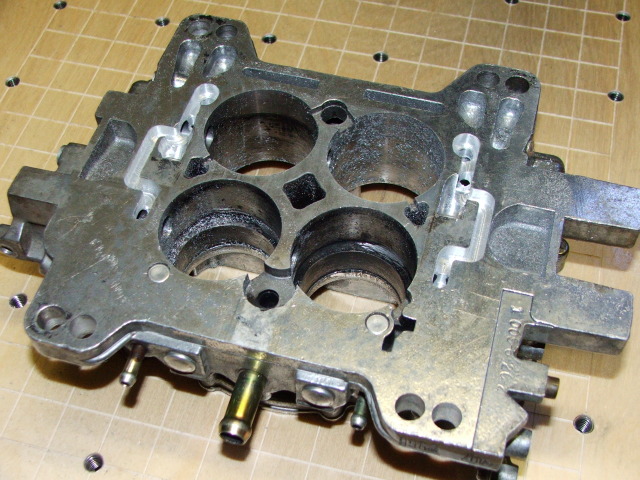

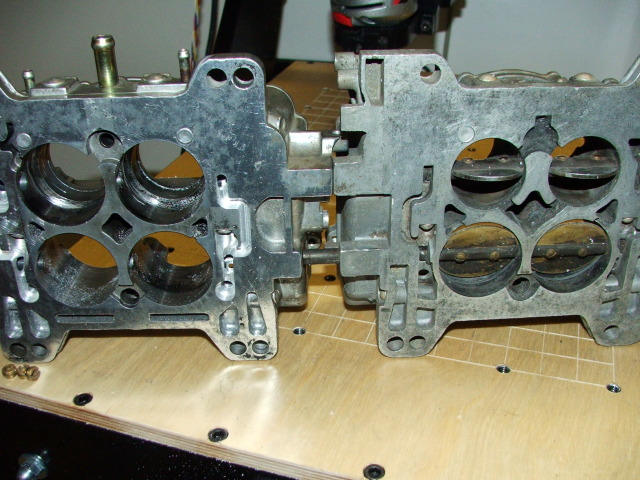

Just a couple pics of the Carter method of sealing the throttle shafts

implemented on an Edelbrock base. Quick and clean, but I cheat by using

a CNC. You can do the same by hand, though. Pressure from above the

throttle plates comes through the secondary airvalve counterweight well

to the passages milled in the base and around the throttle shafts. The

nice part is the same program works for all the Edelbrocks.

Machined Edelbrock base

Edelbrock on the left, Carter R2 on the right

Jim

Often in error, never in doubt

____1966 Avanti II RQA 0088_______________1963 Avanti R2 63R3152____________Rabid Snail Racing

|

Edited by - jlmccuan on 03/03/2010 1:45:42 PM |

|

|

| |

Topic Topic  |

|