| Author |

Topic Topic  |

|

|

sbca96

Commander Member

USA

2499 Posts |

Posted - 03/07/2009 : 7:47:21 PM Posted - 03/07/2009 : 7:47:21 PM

|

The original post got archived and its apparently impossible to take

from archive. It can not be edited while archived, and my pictures

are in a new location since posting.

Originally Posted - 07/19/2006

https://forum.foobar.com/topic.asp?ARCHIVE=true&TOPIC_ID=4957

I got a set of front brake hubs from a guy who had recently upgraded to

Turner disc brakes from his tired 4 wheel stock drums. I pressed the old

drums off the hubs, and then trial fitted the stock hub into the 13" Cobra

rotor, and it fit perfectly - that was a BIG relief! :

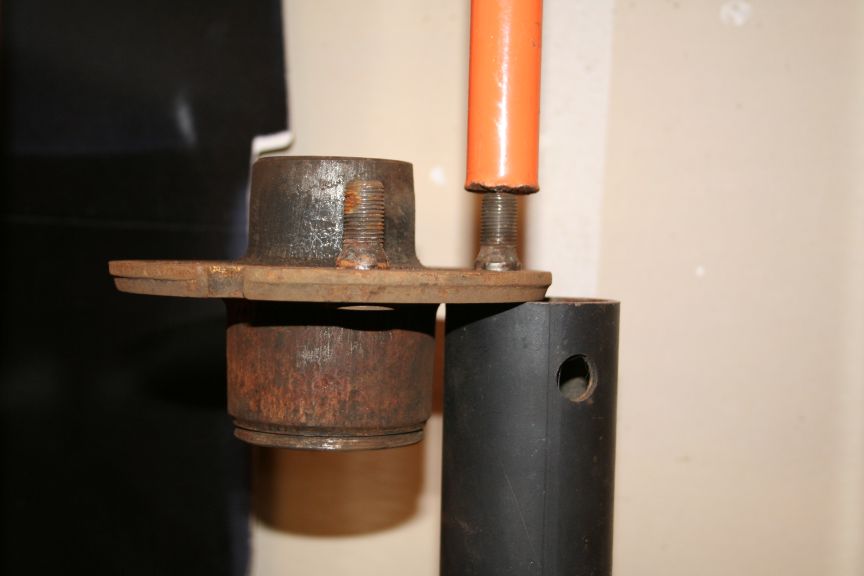

The next step was to press out the old studs :

Here is the studless hub :

Did you know that the factory studs have NO knurl?? No wonder they tend

to strip out so easy with an impact gun!

They looked SOOO ugly, I scraped them with a screw driver, and the took

them to work and used the wire wheel :

Thats all for now .. I had to order the new wheel bearings, seals, caps, and

also make a tool to pound out the old races. The caps I got from Pepboys

in the Help! section, but the part that slips into the hub was too long, so it

would not sit flush, hub against the crimped shoulder. I also bought the 10

Dodge wheel studs mentioned in my original article, and drilled the hub for

the interference fit for the knurl. I took two of the old bearing races, one

of the inners, & one of the outers, and had the machine shop at my work

cut a slot through one side with the chop saw. This will allow me to use as

an installer, so I dont risk damaging the new race with an out-of-control

chisel tip! I went to buy a bearing race installer kit from the local Harbor

Freight, but they were sold out! I will update this thread as I go.

Enjoy!

Tom

'63 Avanti, zinc plated drilled & slotted 03 Mustang Cobra 13" front disc/98 GT rear brakes, 03 Cobra 17" wheels, GM alt, 97 Z28 leather seats, soon: TKO 5-spd, Ported heads w/SST full flow valves, 'R3' 276 cam, Edelbrock AFB Carb, GM HEI distributor, 8.8mm plug wires |

|

|

sbca96

Commander Member

USA

2499 Posts |

Posted - 03/07/2009 : 7:48:19 PM Posted - 03/07/2009 : 7:48:19 PM

|

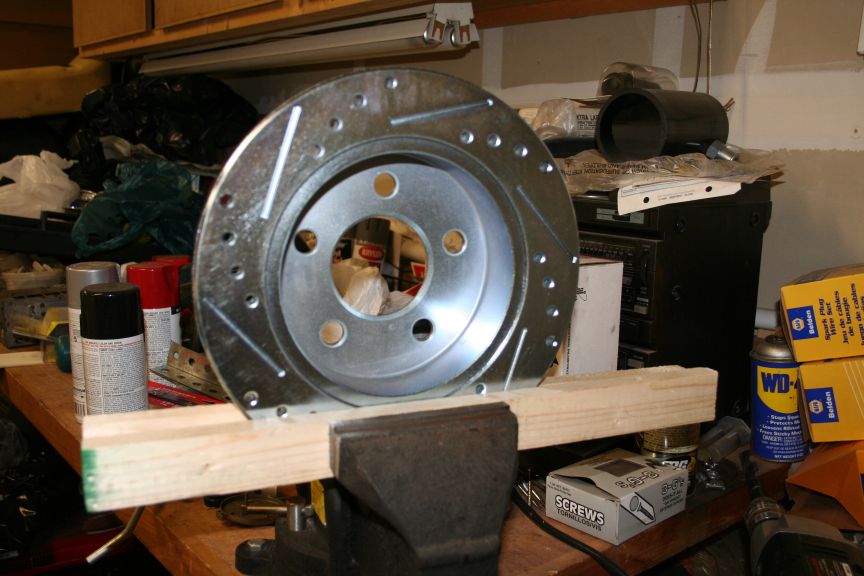

Got out there tonight and drilled the holes out in the new rotors. Thought I

would show a couple pics, the rear rotors had smaller holes, but this could

be because they are "aftermarket". Used the 5/8 drill and went to town:

Rear:

Front:

Sorry about those pics, I dont know WHAT the camera was focusing in on,

it certainly WASNT the rotor. Hummm.

Here is a couple shots of how little material had to be removed from the

front rotor holes, here is one drilled through :

Here is a partial drilled hole. Not a lot to remove :

Close up :

Tom |

|

|

|

sbca96

Commander Member

USA

2499 Posts |

Posted - 03/07/2009 : 7:50:06 PM Posted - 03/07/2009 : 7:50:06 PM

|

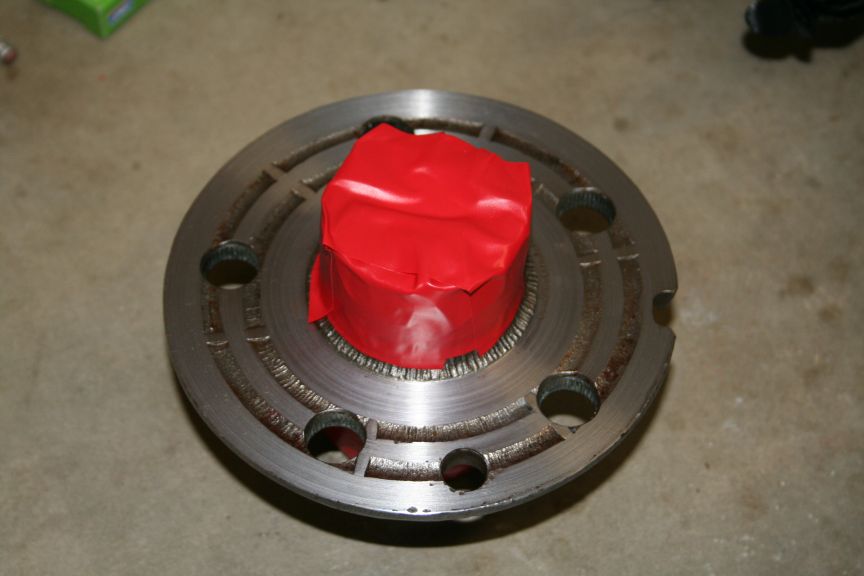

The next step was to remove the old bearing races, & install the new ones.

I added some Loctite & then tapped the new races in until they were flush

with the hub surface. I have installed bearing races this way for years, it

just requires that you continue to hit the race in a "star pattern", like you

torque wheel studs. This keeps the race from getting stuck :

Then I used my two cut old races to tap the rest of the way until the race

was against the machined step inside :

Then I pressed in the Dodge shouldered studs :

Finished hub, waiting to go on the car :

Then I had to remove the Mustang GT rotors, calipers, & the modified hubs

to make way for the unmachined hubs. The machined hubs are going to

Michigan to go on my dads 1969 Avanti II.

Clearance for wrenches is tight, but it works :

Drained out some brake fluid. As you can see, the prototype brackets got

some extra holes, that was to rotate the caliper up, to get the bottom bolt

higher then the steering arm, so a standard wrench could be used on the

top and bottom bolt, and tightened to 85 ft lbs :

Then pack the bearings, add the new seals (Napa now carries an updated

neoprene seal, was glad to toss the old felt ones!!), bolt it on the spindle,

new cotter pin, and add the modified "Help!" dust cap (not a direct fit like a

cross reference site for Studebaker listed!).

Tom |

|

|

|

sbca96

Commander Member

USA

2499 Posts |

Posted - 03/07/2009 : 7:51:22 PM Posted - 03/07/2009 : 7:51:22 PM

|

Once the Dodge studs are in the stock Stude hub, the rotor is an easy step

of tightening the lugs on, to draw the rotor onto the shoulders.

Then, the Cobra caliper gets bolted onto the bracket. With the thickness I

chose for the bracket at the mounting point, I found the perfect length of

bolt at Ace Hardware, though the size could be picked up anywhere.

Here is a shot looking over the Cobra caliper at the lower mounting bolt,

this shows how close the extention is to the steering arm, but it works!

Here is a shot of the upper mounting bolt, again close, but it clears! These

are BIG calipers, so they have a wide spread on the bolts.

Tire back on the drivers side, now off to do the passenger side.

Tom |

|

|

|

sbca96

Commander Member

USA

2499 Posts |

Posted - 03/07/2009 : 7:52:42 PM Posted - 03/07/2009 : 7:52:42 PM

|

I thought I would show the inner hub seals from Napa, the part number is

in the picture. They are nice, because they are not felt, but are a little bit

more difficult to install on the spindle, the rubber edge doesnt slip over on

the seal surface like the felt. I finally used the nut to put pressure on the

seal, and then rotated the hub and the seal popped on.

Hub on the passenger side spindle :

Rotor and caliper assembled :

Unfortunately, I found that the passenger side GT brake hose, does not fit

on the Cobra caliper. The locating boss interferes with the block on the

hose (these are banjo fittings). Not sure how I will correct his, I have the

stainless steel braided hoses, but some prelim comparisons made me think

that the braided lines can not fit where the rubber lines are, since the dont

bend as easily as the rubber! A speed bump .... I'll figure it out!

Tire assembly back on the passenger side :

Is this a freaking BIG brake or what? I guess I have now officially taken

away Steeltech's claim of the "biggest brakes available for Studebaker".

Sorry Dave! Though yours still fit inside 15" wheels. These wont!

Tom |

|

|

|

sbca96

Commander Member

USA

2499 Posts |

Posted - 03/07/2009 : 7:53:06 PM Posted - 03/07/2009 : 7:53:06 PM

|

In my effort to keep you all informed of the good AND the bad in this mod,

here is the latest :

After getting everything together on the car, I took it for the maiden

voyage and it was pretty obvious on the first stop, that something was

not right. The pedal was pulsating pretty good. These were two "new"

hubs that I had to history for, so I did some research on the max rotor

runout thats allowable. The spec I found was .005 at the rotor, which

translates to about .002 at the hub. I checked both sides, and one was

at .007, and the other was over .010! I was able to "correct" the .007

side to .0025 by removing the rotor, and hitting the "high" side with

my trusty BFH (Big Freakin Hammer). The hub was about .003 out, and it

was only in one localized area. A couple sharp blows got me .001 out.

With the rotor back on, that translated to .0025, which is within the

.005 max (.003 preferred). The other hub was .005+ out, & it was over

a 180 degree arc. It was pretty obvious that the BFH wasnt up to the

task of correcting that much error. So off the hub went, pressed out

the studs, and brought it to work and had Bobby take .006 off the front

side. Will try it on the car when I get home (before putting the old

studs back in) and see if its within .002 (.001 preferred).

Heck, if adapting brakes was easy - everyone would be doing it!

Tom |

|

|

|

sbca96

Commander Member

USA

2499 Posts |

Posted - 03/07/2009 : 7:54:08 PM Posted - 03/07/2009 : 7:54:08 PM

|

I think I mentioned that the stock Mustang GT front hoses didnt fit the new

Cobra calipers. The problem was that the boss on the hose end, that the

banjo fitting bolt goes thru, is in a different spot on the pass side caliper.

The GT caliper has the boss in the bottom, the Cobra has it on the top on

both sides. To get the GT hose to fit, I needed to match the boss :

Here is another shot of the steel hose bracket I made. I made a drawing

for this, to make it easier to make another set.

Then I had to machine that hub, to get it right took two tries! It must have

been bent, since the pass side hub only needed a good wack to get it to be

within spec on runout. I would assume that a standard brake lathe could

be used to "true" up a hub before new bearings are installed. The other

fix would be to "true" the rotors with the hub bolted into them. I was not

able to do this, as you arent supposed to "turn" drilled and slotted rotors.

Then I went on too the rear brakes. I could have gone to Cobra rears, but

that would require modifying another set of brackets. I figured that the

GT rears were plenty fine for the 30% left to stop the Avanti. But I wanted

them to match .. so here are the drilled and slotted rears installed :

The old rotors :

Drilled and Slotted rotor installed :

Caliper back on, with new pads of course :

Tom |

|

|

|

sbca96

Commander Member

USA

2499 Posts |

Posted - 03/07/2009 : 7:54:34 PM Posted - 03/07/2009 : 7:54:34 PM

|

Decided since I had the gauge, I might as well check the REAR hubs to be

sure that they were in spec, I didnt FEEL any noticable pulsing with the old

rotors, so I though I was safe. Boy was I wrong. I found the pass side hub

was over .014 out! Thats crazy wobble! I dont know HOW I got away with

that before. I think it might be because I was using used rotors, and they

had a slight runout and I was lucky enough to put them on JUST right???

Regardless, I borrowed a puller, yanked the hubs, & pressed out the new

studs. These should be EASY to turn on the lathe. This wouldnt have been

a problem had I just assumed they needed to be "trued". One thing I had

thought of that could cause the rear to be SO bad. To remove the hubs,

you must use a puller that pulls on the studs, the amount of force involved

could warp the hub a couple thousands each time. This slight amount of

runout probably wont make a difference in a drum brake car, but the max

runout on a disc is .005, and the bigger the rotor, the larger the error is to

be exaggerated. Not a big issue to true up with the hub removed, but the

more material thats removed from the hub surface, the more offcenter the

rotor becomes comparied to the caliper. The calpiers are sliding, so they

with self center, but you could remove so much material, as to make the

caliper bracket interfere with the rotor! (thats a lot of material, but its the

worst case). To remedy this isnt a hug issue, some .005 shim stock could

be used between the hub and rotor to recenter. There are always ways to

get around things that dont go together smoothly (see BFH).

Tom |

|

|

|

stude_s

Starlight Member

USA

69 Posts |

Posted - 03/08/2009 : 12:56:00 AM Posted - 03/08/2009 : 12:56:00 AM

|

Tom,

As always great work and thanks for keeping us all updated on the progress with these modifications/upgrades. They sure are looking great!

Steve

|

|

|

|

sbca96

Commander Member

USA

2499 Posts |

Posted - 03/08/2009 : 01:04:59 AM Posted - 03/08/2009 : 01:04:59 AM

|

Thanks Steve, but this is a repost (RP) of the archived article, your

positive comments are certainly welcome, just clarifying that this is

about 2 years ago (not that much else has come about since then). The

yer 2008 was a complete waste, as my wifes recovery from surgery and

the accident resulting in totalling her car all started the year. My

injuries put me behind on the Avanti, and the search for a new car to

replace her "baby". Hopefully soon I can refocus on the Avanti and do

the Cobra rear brakes to match.

Tom |

|

|

| |

Topic Topic  |

|

|

|