| Author |

Topic Topic  |

|

|

sbca96

Commander Member

USA

2558 Posts |

Posted - 12/01/2008 : 03:46:24 AM Posted - 12/01/2008 : 03:46:24 AM

|

Originally posted Posted - 02/23/2006 : 01:34:35 AM

The original post was locked/archived, so I could not update the links

for the pictures, so here is a repost :

Edit per new picture location : 12/1/08

Well ... I guess I will share what I have been doing on my Avanti

lately. As many of you might remember I bought a set of rims for

it - 2003 Mustang Cobra rims.

Well, one problem I found that I had was the rim would contact the

upper A-arm pivot in the front on a turn, this is bad for the rim!

I contacted a guy back east who sells a 12 inch rotor disc brake

setup that bolts on. The problem - its $650 plus shipping. I also

want to upgrade my rear brakes, he sells a rear disc kit, but there

is another problem - its $450 plus shipping. I wouldnt be that I wouldnt be that

concerned, but after sending out the $4250 check to the RIAA, I dont

have much left over for the mortgage, let alone brakes for a car I

rarely drive. The Avanti brakes need to be completely refurbished,

so even if I decided to keep the stock brakes, I am looking at over

1500 dollars in vintage discontinued brake parts ...

But .. along came my Mustang friend. See, Ford uses the SAME 5 on 4.5

inch wheel pattern (obviously since I could bolt the rims on) so the

rotors will fit my hubs also. My Mustang friend GAVE me his whole

1998 GT disc setup when he upgraded to Cobra brakes. 11 inch vented

front rotors, calipers, rear solid rotors, calipers (with parking

brake), and axle brackets. Since I am a CAD operator, I took the

dimensions of the bracket, and drew them up in CAD, I also got the

dimensions from the Dana 44 axle. It looks like the rear setup will

require some milling to thin the bracket a bit to move the mounting

surface out, and then a bolt pattern change, and open up one side so

it can slip over the axle tube and mount on the backside of the axle

flange. It will use three bolts to attach, which is common with a

disc brake caliper retrofit. The rotor will fit over the hub, and it

looks like the tapered backside of the stud holes, will nicely center

the rotor on the studs. Hopefully I can have the brackets modified

this next week at my work.

The front is a different story. I didnt get brackets, as the caliper

mounts to the spindle. I did some research and found a guy who makes

brackets to mount 03 Cobra brakes on a first Gen Mustang. I pulled

the image off his website and then imported it into CAD, then traced

it to get the basic angle and spacing from hub center for the caliper.

This is important to keep, as bleeding would become difficult! So,

armed with this new info, I felt good about using the GT front brakes

as well, you have more drive to adapt something when you get it for

free!! But, I ran into a problem. The Stude wheel hub is a larger

diameter then the inside diameter of the Ford rotor! darn! This is

not the end of the world, as I can have the wheel hub machined to the

right size, removing metal is easier then putting it back. The rotors

on the Avanti are junk anyway. So I wasnt able to take the next step

of dimensions, so that I could continue with my brackets. I did some

research tonight on the web, looking to see if there was a hub that is

the right size for the rotor, that would fit my spindle - no dice. I

would rather use the Stude hub if I can, and the bearings are still

available. Interesting though, the 1994-04 Mustang hubs are NOT able

to be repaired! You can NOT put in new bearings! No joke! Now I

could get the hubs from my buddy (he mentioned that a bearing is now

making some noise, and then have my buddy at work machine the inside

to fit the Stude bearings, but .. thats a pain (though a possibility).

Back to the spacing problem, it looks as though moving the wheel out

1/4 inch will solve the clearance problem. The Stude rotor is mounted

on the backside of the hub, so it doesnt effect wheel position, but the

Mustang rotor is on the outside, between the rim and hub, and the

rotor thickness is .275, just a tad more then 1/4 inch. So if I can get

this to work, then it will work beautifullly with these rims. Though it

would not work well with stock steel rims, as the caliper position will

cause contact with the steel rims. Right now, because of the design

of the Cobra rims, the stock Stude brakes look pretty silly sitting WAY

back, and looking quite small. The NICE part about this swap, is the

Cobra uses the same hub, and caliper mount position as the GT, so

I can EASILY upgrade to 13 inch rotors and 2 piston calipers in the

future ... nice huh??

Tom

'63 Avanti, zinc plated drilled & slotted 03 Mustang Cobra 13" front disc/98 GT rear brakes, 03 Cobra 17" wheels, GM alt, 97 Z28 leather seats, soon: TKO 5-spd, Ported heads w/SST full flow valves, 'R3' 276 cam, Edelbrock AFB Carb, GM HEI distributor, 8.8mm plug wires |

|

|

sbca96

Commander Member

USA

2558 Posts |

Posted - 12/01/2008 : 03:46:50 AM Posted - 12/01/2008 : 03:46:50 AM

|

Sorry about the focus on some of these pictures ....

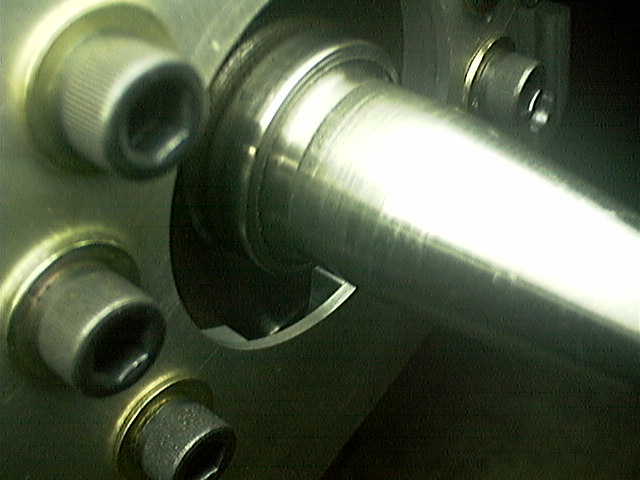

The Studebaker hubs are now modified to accept the Ford rotors with the rotor lug

holes drilled out to the next SAE size - 5/8. The original Ford rotor holes being

metric these days. Here is the stock hub after separation - before mod :

The Ford rotor is 5.6 inchs in diameter where the hub needs to fit, the outside of

the hub was turned down to 5.5 inches, if you were to want to go with the Cobra

13 inch rotor from the start, I am assuming that the Cobra has more room in the

back, but this is not verified yet. I know that the rear rotor will fit the stock Stude

hub without being turned down:

I used Chrysler wheel studs, which are for a 1/2 and 3/4 ton truck from the 70's

all the way to 2003 - nice huh? Wide array of availability. Napa part number is

BK6412184, they come in boxes of 5. The only problem in using them is they are

for a larger hole. The Stude knurl is .645, but the knurl on these studs is .668. I

used a 21/32 drill to give me ~.012 of interference fit, then added Loctite. It is

pretty easy to do, with a hand drill and a vice. The studs are 1 3/4 inch long, with

a shoulder that would extend out to center the rotor.

I found that the old Stude rotor makes a perfect holder for the hub when pressing

the studs in, nice and stable. I might mention that one of the hubs on my Avanti

was a drum brake hub, with a disc pressed on the back, so I know that this will

work for either hubs. I found that the disc brake hub, accepted the stud straighter

then the drum brake hub. This is because the drum brake hub is not machined on

the back. This was easy enough to "fix", by putting the rotor on the hub, and then

tightening the wheel on to draw the rotor onto the hub. This straightened the studs

to the correct position (since the tapered hole in the rim will force the stud to

perpendicular to the hub face). I didnt have to do this with the disc brake hub.

Tom |

Edited by - sbca96 on 12/01/2008 03:51:06 AM |

|

|

|

sbca96

Commander Member

USA

2558 Posts |

Posted - 12/01/2008 : 03:47:21 AM Posted - 12/01/2008 : 03:47:21 AM

|

Here is the finished hub - ready for a Ford rotor!

Here is the difference between the stud rotor and the Ford, the Stud is non-vented

and only about 3/8 thick, each half of the Ford rotor is 3/8 thick. The Stude one

worked great in its day, and still is good for a few stops, but I wouldnt trust it on

a twisty auto cross course! ;)

Here is the dinky little bracket that holds the stock Stude caliper in place, it only

uses three of the available 6 holes, and mounts on the back side.

Compared to a Craftsmen 9/16 wrench .... so cute!

Here is the hub and the spindle flange just waiting for the new brackets to come

out of my head:

Sorry, I didnt get a shot of the rotor on because the battery in the cam died, but it

does fit and spins true. The thickness of the rotor made the passenger side clear

perfectly and the drivers side almost clear the upper A-arm. It is driveable now (if

the brakes worked), I think that I will use an 1/8 spacer in between the rotor and

the wheel, the wheel studs are long enough to handle this. They are larger studs

then Ford used anyway. I took all the dimensions that I needed to draw up the

brackets in CAD, they look fairly simple to do.

Tom |

Edited by - sbca96 on 12/01/2008 03:51:59 AM |

|

|

|

sbca96

Commander Member

USA

2558 Posts |

Posted - 12/01/2008 : 03:48:00 AM Posted - 12/01/2008 : 03:48:00 AM

|

Well ... here is the next step in the Mustang GT brake project : test bracket. Its

always best when prototyping, to test your dimensions before going to metal. I

used some masonite to fab a rough bracket and test the design.

Here is the test bracket mounted on the spindle :

The large radius is to clear the massive wheel cylinder on the front caliper.

Here is the modified Studebaker hub mounted on the spindle:

Then we slip the Mustang rotor over the studs (with the metric holes drilled to the

next size SAE : 5/8):

And finally test fit the caliper onto the bracket to see how we did:

Turned out that I got pretty close on my first try. The only drawback was the lower

caliper bolt is right in line with the steering arm on the spindle. Not really a HUGE

problem, there are some tools that will allow the torquing of the bottom bolt, its

just nice when everything clears perfectly. Other then that, all looked great, now

to mill some 6061-T6!

Tom |

Edited by - sbca96 on 12/01/2008 03:52:30 AM |

|

|

|

sbca96

Commander Member

USA

2558 Posts |

Posted - 12/01/2008 : 03:48:25 AM Posted - 12/01/2008 : 03:48:25 AM

|

Masonite just doesnt compare to the look of machined aluminum. My work has a

lot of odd sized 6061-T6 scrap laying around, and even though my first choice was

to go with 7075-T6, you can not beat the price of free. Doing a comparison in the

strength of each, and steel .. the yeild and the expansion, it seemed that 7075 was

overkill anyway. But, I used 3/4 thick 6061-T6 - just in case.

Here is the drivers side bracket mounted on the spindle :

Using 3/4 inch thick aluminum gave me the opportunity to create a grease cavity

in the back side of the bracket. This is something that Studebaker used at all four

corners of the car, it is there so that if a grease seal was to fail .. the grease will

ooze harmlessly out the back .. and not end up on the drum or disc.

Here is a view from further back, sorry about all the grime and crud, I wasnt in the

mood to clean any more then I have too to check fitment. Once I swap out the GT

rotor and caliper for the big Cobra stuff, I will scrape and paint everything.

Here is the hub back on, and as you can see, designed in the bracket inner dia lets

the hub sit inside of it ... so if the grease seal fails ...

Now on to the passenger side, a mirrored bracket :

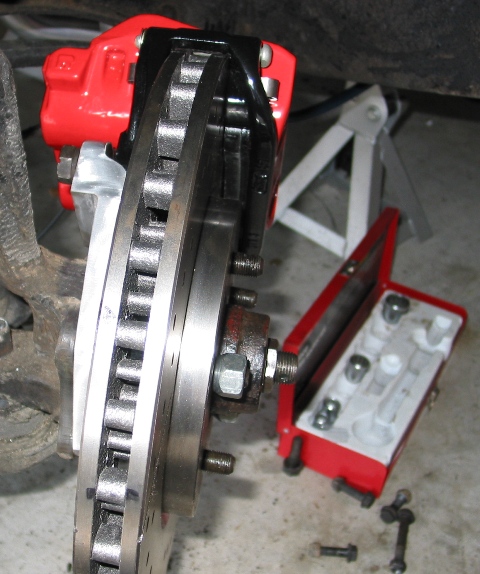

The rotor and caliper mounted :

There they be! Ofcourse the next step is to attach the Mustang brake lines to the

Studebaker frame, and for that the factory Mustang brackets didnt work, and the

factory Studebaker ones didnt either. So ... time to cut and bend and weld!

Tom |

Edited by - sbca96 on 12/01/2008 03:53:08 AM |

|

|

|

sbca96

Commander Member

USA

2558 Posts |

Posted - 12/01/2008 : 03:48:49 AM Posted - 12/01/2008 : 03:48:49 AM

|

After jacking the car up so that the wheels dangled, I figured that THIS would be

the "Worst Case" senario for the rubber brake hoses. I would end up trying quite

a few different locations and angles of the hose end before decideing on the best

position. The hose needed to be able to flex without rubbing anything throughout

the travel of the suspension and the turning of the wheel. What a pain! I found

that the stock Mustang brackets needed to be 90 degrees from what they were.

So I cut off the "business end" and then bought some steel stock. I wanted to use

the existing holes in the frame to bolt it down and locate it so that it wouldnt turn.

Here they are!! :

I dont know how to weld, but the supervisor of the machine shop will weld simple

parts for fast food fries. These cost me a large fry from Mc Donalds. This next pic

shows WHERE these go, I bet now it makes sense.

A close up ... pretty aint she?

And of course one for the other side as well :

The hoses dont contact anything when the wheels turn back and forth and the only

modification to the hose was an adapter fitting on the DRIVERS side to turn the

larger flare to the size Studebaker uses. Strange, but the PASS side was the same

size as Studebaker and didnt need to be changed. The wrench needed to tighten

the hose was a metric, but the flare was SAE - go figure.

My dad and I drove around and the brakes worked AMAZINGLY well. I had hoped

for an improvement, but there is NO comparison. Granted the old brakes were in

pretty bad condition, but the addition of a vented rotor will help cooling. I plan on

switching to the 13 inch Cobra brakes as soon as I get my tax refund. My dad

wants the GT parts for his Avanti.

Is anyone interested in something like this being marketed? I feel that by using

the original hubs, it really reduces waste, and doesnt require buying hard to find

rotors or using sleeves. Not to put down the great work that others have done to

keep Studes on the road, but I think there is always room for another viewpoint.

Shoot me an email if interested : sbca96@aol.com

Now I am working on the rear disc setup ... the brackets are done, and on the axle

and I am modifiying the hubs with the Dodge wheel studs. The outer dia of the hub

doesnt need to be machined down, because the inner dia of the Mustang rotor is

larger then the front and the Stude hub is smaller - perfect fit. The rotors actually

fit fine, but its recommended to have at LEAST 8 threads of contact on wheel studs

and I was at 5 with the stock length studs. I ordered the stock Mustang rear hoses

for the setup, because I didnt get those from my friend. I was happy to find that

Autozone includes the banjo bolt in the hose kit. Before you laugh, they are nice

hoses made by Wagner. Now I have to figure out the plumbing, once I get all the

wheel studs in ... had a mishap with one of the 5 studs I COULD get (darn the

StupidBowl, most the autoparts stores closed early today!), it contacted the socket

that I was using when pressing the stud in, and ruined the threads on the stud.

GRRRRRRRR!

Oh well .. gotta buy 6 tomorrow now.

I must also mention that "Bobby" the machinist thats been doing all the work for

me after hours, has been absolutely wonderful. If it wasnt for his patience with

the sometimes last minute and "on the fly" design changes this wouldnt have even

happened. Even the slight "correction" that we had to do on the rear brake caliper

brackets he didnt cringe (much) at. Thanks Bobby!! You dah Man!

Tom |

Edited by - sbca96 on 12/01/2008 03:53:52 AM |

|

|

|

sbca96

Commander Member

USA

2558 Posts |

Posted - 12/01/2008 : 03:49:22 AM Posted - 12/01/2008 : 03:49:22 AM

|

I thought that I would share what the Cobra brakes will look like, the calipers

come in both black and red (that I am aware of) and are actually 2 piston, not

4 piston like I had originally mentioned (thanks Ed and Eric for setting me

straight on that!). I got confused with the Baer 4 piston setup that my friend

had converted to (which got me the GT brakes!). If memory serves there is

an 8 piston caliper also available, but thats CRAZY talk!

These images were "borrowed" from

https://www.edbert.net/brakes.htm .

After doing brake pads on my 1993 Camaro Z28 for the last 10 years, I had

thought that the Stude hubs could be modified to allow a "slip-on" rotor to be

used (like most newer cars). After finding out that Ford still used the same

bolt pattern as years ago, I knew that the Ford rotors would fit. After getting

Ed's brakes .. it all came together. When looking for the dimensions of the

angle of the caliper position, I came across "Mustang Steve" who makes a kit

that allows the installation of Cobra brakes on a first gen Mustang. It was his

website that I got the angle I needed. He was also very helpful by telling me

that Ford still used SAE flare thread (https://www.mustangsteve.com/).

10 inch rotor compared to the 13 inch Cobra:

Other assorted views :

I checked the fitment of a stock Studebaker wheel on the new brake setup, it WILL

NOT fit, due to the caliper being out farther to the wheel. This brake setup

would require upgrading to wheels that fit a 1994 to 2004 Mustang. This can

be viewed as good OR bad depending on your perspective. At least with the 11

inch GT Mustang calipers, you can run a 15" wheel. I have been told that this

can be done with a Lincoln Towncar (early '90's) 6.5" rim width and the offset

is ~0.5" farther out than Stude. I havent checked this personally though it

sounds like it would allow the use of the 11" rotor/GT caliper and Stude full

size wheel covers.

Tom |

|

|

|

tim87114

Starlight Member

USA

72 Posts |

Posted - 12/01/2008 : 1:02:42 PM Posted - 12/01/2008 : 1:02:42 PM

|

Tom,

Did you happen to pull the following dimensions from your spindle,

Inner bearing surface measurement

outer bearing surface measurement

and total length of spindle?

I have a 48-49 champion that I am going to convert to disc brakes. I was out at the salvage yards pulling rotors and measuring spindles.

My spindle is 1.25" at the inner and .75" on the outer. I need to re-measure the spindle length as my notes mysteriously vanished :).

I'm not familure with Avanti's but it looks like stock they run a hub assembly on the spindle?

This would be ideal as it is the route I've been looking to do. I'm finding all ford stuff from 92 up do not run a "tapered" spindle and hub. However I am finding other makes that are. I'm hoping to get back out to a different salvage yard to know for sure. |

|

|

|

bowss@aol.com

Starlight Member

55 Posts |

Posted - 12/01/2008 : 1:43:59 PM Posted - 12/01/2008 : 1:43:59 PM

|

| Instead of milling the rear end for disc brakes look at the 8.8 rear ends from late 1980 to early 1990 Ford Explorer. They come with a disc brake setup (earlier models are drum brakes which are easily converted to disc brakes. Lokar makes a cable hookup kit for the park brake. The only change you will need is to remove the spring pad mounts and move them about 3/4". For the Hawk models this rear end is a stouter unit than the Dana 44. |

|

|

|

ClaymoreWW

Regal Member

USA

479 Posts |

Posted - 12/01/2008 : 2:26:23 PM Posted - 12/01/2008 : 2:26:23 PM

|

wow! very nice! Better stopping AND replaceable parts!

--george

1963 Lark Daytona HT - 63V J8 175

|

|

|

|

sbca96

Commander Member

USA

2558 Posts |

Posted - 12/01/2008 : 4:17:52 PM Posted - 12/01/2008 : 4:17:52 PM

|

quote:

Originally posted by tim87114

I have a 48-49 champion that I am going to convert to disc brakes. I was out at the salvage yards pulling rotors and measuring spindles.

I think you will be pretty much SOL finding a modern hub that will fit

the Studebaker spindle. I didnt bother to measure the spindle because

I just reused the Studebaker hub. That simplifies the install. This

is what the modern cars do, Studebaker did this to some degree, as the

hubs & drums, and hubs & discs are two piece. The drums are between

the wheel and hub, where as the discs are held to the backside of the

hub with special wheel studs. I just moved the disc to the outside as

the modern cars are. If you are planning something of this nature, I

would suggest using your factory hub, and keep that relationship fixed.

I hope that helps.

quote:

Originally posted by bowss@aol.com

Instead of milling the rear end for disc brakes look at the 8.8 rear ends from late 1980 to early 1990 Ford Explorer.

Thanks for the input, but as this is a repost, I have already been

running the matching Mustang setup on the rear, it was completed in

the months following the original post. I have to find the text to

it and I can repost it here to keep the info together. The install

is pretty much like the front, with the Ford brackets being redrilled

to mount the caliper to the Dana 44. I still havent done the parking

brake, but Karl had put something together. The Mustang rear caliper

is the same for the Cobra and the GT (for the most part) and use a

pull type setup. The mod looks very easy, its just been backburnered.

quote:

Originally posted by ClaymoreWW

wow! very nice! Better stopping AND replaceable parts!

Thanks George. If you wish to be added to the update list I am doing

CNC brackets, one set is still available at this time.

Tom |

|

|

|

sweetolbob

Golden Hawk Member

USA

552 Posts |

Posted - 12/01/2008 : 5:45:02 PM Posted - 12/01/2008 : 5:45:02 PM

|

Tom

Thanks for a great article. Wish I had known this when I added discs to my 54.

Tim

I think you need to look for mid 80's GM midsize rotors, possibly Monte Carlo. They require a new set of bearings with GM OD's and Studebaker ID's. A pretty standard way of changing hubs over the years. Of course, the down side is incorrect bolt pattern, no bad to change.

Bob

|

|

|

|

tim87114

Starlight Member

USA

72 Posts |

Posted - 12/01/2008 : 7:29:04 PM Posted - 12/01/2008 : 7:29:04 PM

|

Bob,

In my looking around besides going to the salvage yard to get some hubs I was thinking back to the farm and remembered we used hubs on all our trailers. I did some looking and sure enough I can get them in what ever bolt pattern and bearing combo I would need. They are pretty cheap new as well. My only hang up would be knowing the exact spindle length they require vs a car hub.

I'll check the GM cars too. Plenty of those in the junk yard for sure. |

|

|

|

sweetolbob

Golden Hawk Member

USA

552 Posts |

Posted - 12/01/2008 : 8:00:23 PM Posted - 12/01/2008 : 8:00:23 PM

|

Tim

Measure the Stude hub from bearing outside to outside, same with the hub you are examining. I'll bet they are close. If one is wider, I'll bet it is the Stude hub. The difference is the width of the spacer needed.

Be sure to buy new rotors, they are cheap as are the rest of the parts. What you are doing is the same as assembling a kit to convert early ford hubs to disc brakes.

Bob

|

|

|

|

sbca96

Commander Member

USA

2558 Posts |

Posted - 12/02/2008 : 11:14:26 AM Posted - 12/02/2008 : 11:14:26 AM

|

Curious why you dont want to use the factory hubs? The bolt pattern

is something oddball? It was critical for me to keep the stock spacing

between the bearings. I didnt want to stress the spindle by moving

the load in or out. Studebaker spindles are quite long, I dont know

if that is true for the earlier years. Late model cars use assemblies

that arent usually rebuildable. The whole spindle/hub is replaced as

a unit, held in place by 4 bolts at each wheel. The Stude spindle is

smaller in diameter than these modern setups. I guess thats how they

get away with moving the bears closer together.

There are a number of different modern bolt patterns available. Ford

still uses the Studebaker one, GM has two 5 on 5 and 5 on 4 3/4.

I wish the original thread was a sticky, so more could see what I did.

I've invested money into having the brackets made by a local CNC shop.

As I mentioned I have to design the final rear bracket, though a proto

exists on my Avanti already. The reason this is a herdle, the GT is

a smaller rotor than the Cobra. The caliper is the same, so they made

the bracket hole spacing from center different. To make brackets I'm

hoping to make one bracket that does both applications. The front is

already this way, Ford used three different calipers in the front. I

hope that makes sense.

Tom |

|

|

|

tim87114

Starlight Member

USA

72 Posts |

Posted - 12/02/2008 : 3:45:48 PM Posted - 12/02/2008 : 3:45:48 PM

|

Ah, Ok, Ya know I never looked at the Drums when I pulled them off. I stripped the spindle down but just set the drums to the side knowing I'd have to replace them. I need to check to see if the "hub" comes off the drum on my model/year of studebaker. I'm not sure at this point.

Also, on 47-49 it is a 4 lug bolt pattern. I'm going to use a ford Explorer rear which will change my bolt pattern to 5 on 5.

So after reading your post I'm figuring I need to source a hub. Also, I need to verify the mounting locations of the spindle bracket for the caliper. I take it your brakets are available? |

|

|

|

sbca96

Commander Member

USA

2558 Posts |

Posted - 12/02/2008 : 4:16:37 PM Posted - 12/02/2008 : 4:16:37 PM

|

Yes, my brackets are available. You can have your old hubs redrilled

to match the rotor you want to use. You COULD even have a machine shop

make you some billet hubs to YOUR specification. There are a lot of

possibilities. You might be surprised how inexpensive some of this is

if you find a shop needing work - something thats pretty common these

days. There are also a lot of 4 bolt rotors available. You need to

figure out what the bolt spacing is, and then who still uses it.

Tom |

|

|

| |

Topic Topic  |

|

|

|