| Author |

Topic Topic  |

|

|

Lark Parker

Regal Member

USA

260 Posts |

Posted - 01/30/2008 : 9:03:43 PM Posted - 01/30/2008 : 9:03:43 PM

|

Links to same subject postings:

https://www.studebakerdriversclub.com/sdc_forum/topic.asp?TOPIC_ID=15898

https://www.studebakerdriversclub.com/sdc_forum/topic.asp?TOPIC_ID=16092&SearchTerms=Stainless,restoration

https://www.studebakerdriversclub.com/sdc_forum/topic.asp?TOPIC_ID=15554&SearchTerms=Stainless,restoration

https://www.studebakerdriversclub.com/sdc_forum/topic.asp?TOPIC_ID=15349&SearchTerms=Stainless,restoration

https://www.studebakerdriversclub.com/sdc_forum/topic.asp?TOPIC_ID=15234&SearchTerms=Stainless,restoration

https://www.studebakerdriversclub.com/sdc_forum/topic.asp?TOPIC_ID=15153&SearchTerms=Stainless,restoration

https://www.studebakerdriversclub.com/sdc_forum/topic.asp?TOPIC_ID=15021&SearchTerms=Stainless,restoration

https://www.studebakerdriversclub.com/sdc_forum/topic.asp?TOPIC_ID=15067&SearchTerms=Stainless,restoration

Stainless Restoration #9, Wheelcover. Wow! Rare!

Copyright 2008 Dale McPhearson, all rights reserved. Published with permission.

This time we will do a 53-55 wheelcover. This was picked because it is plain enough to not clutter up the pictures. The demo is mostly about using preferred directions of sanding and buffing. Therefore, just pretend the cover has a dent and the sander and buffer are turning.

As was stated before in this series, my way is just my way and if you find a better way, don't worry about it. Be secure in your ways. I find it safer to use buffers and sanders that are not turning. You may wish to turn yours on.

I have made special tools for some of these jobs because in the long run they save me time and effort to get a good result.

This type wheelcover is easy to dent, even with the palm of the hand. When you are too manly putting them back on and hit them on the cone you may not be pleased. If they have PITS in them or damage near the edges they are not repairable for show. Sanding out many PITS generally weakens such a flat surface. A few pits can be bumped out with a punch. I use the handle end of the hammer to tap the punch lightly.

The doubled metal lip makes dent removal impossible in that area.

This hammer can also be used on portions of other wheelcovers as they have similar contours. Sometimes a mildly dented cover can be made more presentable for a driver with just dent removal and no sanding or buffing.

The hammer is made by welding a 3 1/4" freeze plug onto a light hammer and then trimming the vertical face dimension to 1 3/4". The trimming is done to make it easier to use and better visibility.

The hammer is only for imaginary dents that go in. Don't use it for imaginary dents that go out. The contour is wrong.

DON'T DO THIS. A body hammer will leave dents at the side edges because the face is not convex enough in shape. The body hammer face is generally too small in area anyhow. The force to straighten should be over a larger area for this thickness and shape metal.

You can do this if you want, I don't care. Ok for small out dents.

But it won't take much to give you an another inward dent to practice taking out.

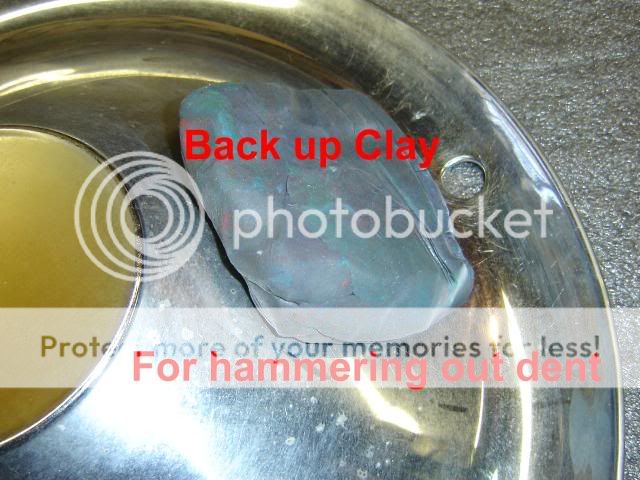

This is a large lump of PlaySkool clay and makes a great backing for tapping on contoured shapes. This is two boxes of the red and blue mixed together. I save the yellow and green for Speedsters as it dfoesn't show up so bad in the spokes.

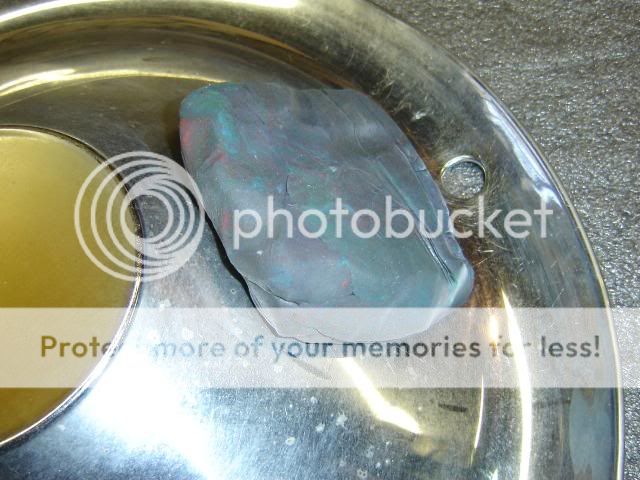

This is the other side from the clay. Nothing to see there but an imaginary dent poking up at you. Hammer there, lightly.

This is the clay after it has shaped itself to your job. Clay makes a wonderful deadener. I keep it in a plastic bag and sometimes leave the bag on it while using it to keep the oils(?) from getting on the stainless, and the clay stays cleaner.

After taking the dents out sand with a CIRCULAR sander (NOT ORBITAL) in the direction shown.

This is the wrong direction. You can also tell because red letters will appear reading "DON'T DO THIS"

Now for the buffing. I hold the cover differently than I would for any other pieces, except stone guards. Standing at the end of the buffer, I work the cover on the bottom of the wheel. One hand at 9 o'clock,

one hand at 3 o'clock, and the belly button at 6 o'clock. Starting at the 12 o'clock hole for the valve stem, move in and out in a sensual motion for about ten strokes. If done correctly, you will be engaged to the wheel cover by the time you are done. Progress around the cover overlapping the areas.

This method gives an uneven appearance. If that's what you are shooting for, go ahead.

If you end up at U or W instead of V then the cover is ruined. Send it to me to discard.

Lark Parker Lark Parker

If at first you don't succeed -- you will get a lot of advice.

|

|

|

Karl

Regal Member

USA

387 Posts |

Posted - 01/30/2008 : 11:08:36 PM Posted - 01/30/2008 : 11:08:36 PM

|

Can this buffing process to bright and older set of Avanti wheel covers. Less letters because of the painted surface..hehehehe

|

|

|

|

Lark Parker

Regal Member

USA

260 Posts |

Posted - 01/31/2008 : 03:59:20 AM Posted - 01/31/2008 : 03:59:20 AM

|

Lookimg back at the pics, I don't think I made it very clear that the sandimg pattern is to result in concentric circles.

Regarding 1951-52 wheelcovers, for show purposes I would recommend that the reproduction covers be seriously considered. For me, the metal in the original 51-52 covers did not respond like others have to this treatment. I was able to improve them but not to my satisfaction.

Karl, are you sure the Avanti covers are metal? <g> Just about any method on anything may be modified to fit the real world --- as long as you end up on V.

Lark Parker Lark Parker

If at first you don't succeed -- you will get a lot of advice.

|

|

|

| |

Topic Topic  |

|

|

|