quote:

Originally posted by sbca96

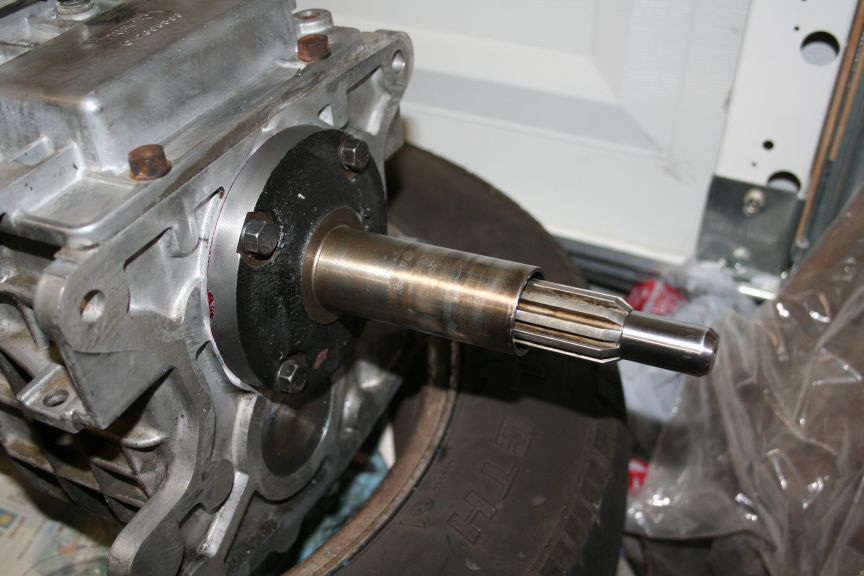

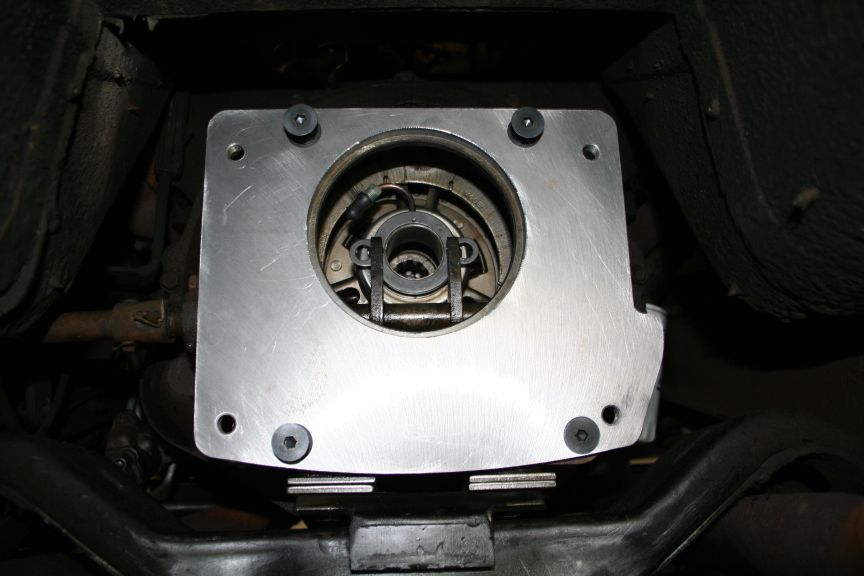

Short update, I received the input shaft extention in the mail this

weekend, and removed the input shaft. I followed the instruction in

the manual, but 17 little roller bearings STILL fell out inside the

transmission when I CAREFULLY pulled the input shaft out. For those

who end up with the same problem, I used a little telescoping magnet

to retrieve them through the drain plug hole at the case bottom. At

inspection of the front bearing, the race looks worn, and the rollers

also.

The trick is, Dan put an interference fit to hold it tight to the tip

of the input shaft. The process of heat treating the 01 Tool steel

is to heat to 1200 degrees F and cool in oil. While the piece is at

1200 degrees, it will easily slide onto the input shaft. My work is

versed in how to do this process, so I will hand it off to Guy again

and let the experts do their thing!

Tom

Reply

Reply

Thanks for the update

Thanks for the update